In my last post (In Praise of American White Oak) I spent a lot of time talking about the various qualities that make American white oak so suitable for the barrels used to mature Bourbon and rye whiskey. However, I deferred discussion of degrading, a set of processes which prepare oak for its critical role in the whiskey maturation process, because I thought these merited a post of their own. Let’s get into these now.

First here’s a quick recap from the previous post, starting with the primary constituents of wood:

Cellulose & Hemicellulose: These are the two polymers that provide the rigid structure of a tree. These compounds don’t generally contribute much

to barrel aging unless modified by weathering/heat.

Lignin: Another class of polymers that fills in the spaces between the cellulose and hemicellulose. When lignin is toasted and charred (more on this below) it will interact with ethanol and oxygen to create many new compounds.

Living trees use a network of vessels constructed out of these structural components that run vertically and horizontally for the purpose of transporting water and nutrients between the roots and the tree top (or crown). This is akin to a circulatory system. When a tree is harvested for timber (and dies) this system is left more or less intact.

After trees are harvested, they are cut into sections and then quarter sawn into billets. The technique of quarter sawing preserves the integrity of the anatomical feature in the oak known as multiseriate compound medullary rays thus ensuring the barrel will be ‘tight’ (to use the cooper’s term) which is to say it will be capable of holding a liquid like whiskey. [1]

Once the oak has been sawn into billets, they are ready to be degraded.

Degradation techniques take several forms and most involve heating of some sort. This results in what’s usually described as a radical depolymerization of the wood’s constituents, which has several effects:

— Readies wood to absorb the whiskey when the barrel’s filled

— Creates new compounds which contribute to aroma and flavor

— Reduces levels of undesirable compounds

— Provides almost all the color in a whiskey in the form of the char layer

There are two primary ways oak is degraded: first by seasoning and kilning, second by charring and toasting. We’ll discuss each of these complementary techniques below.

Seasoning and Kilning

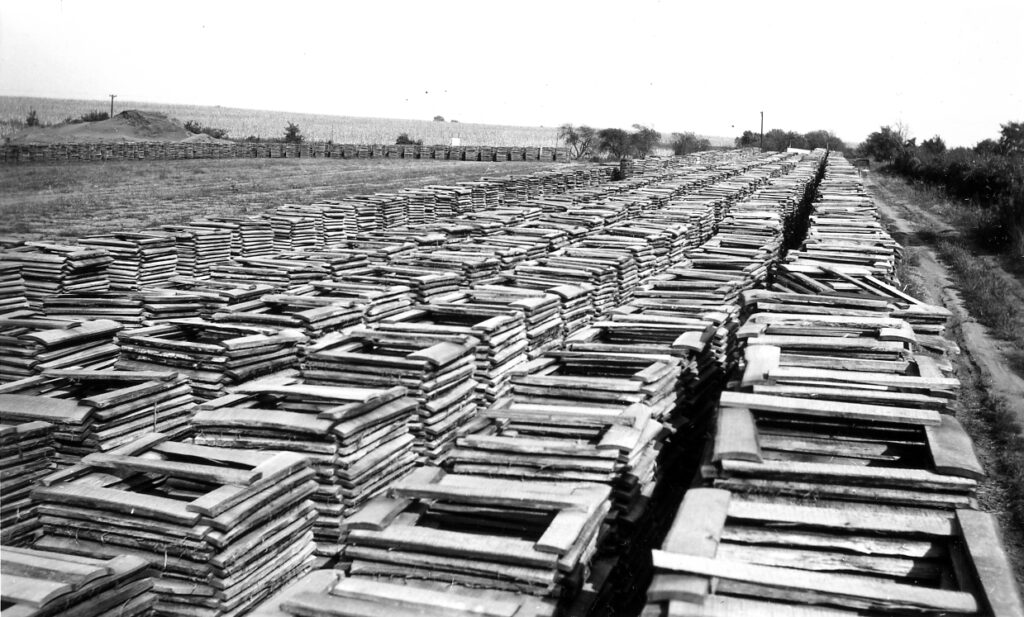

Seasoning (sometime called ‘yarding’) involves leaving the raw billets (which will eventually be formed into barrel staves) stacked outside, unprotected from weather. The wood structure is distressed by exposure to UV in sunlight, oxygen in the air, temperature changes, and can even be ‘colonized’ by fungi and algae. The billets will lose some moisture content during this time (which is a bit counter-intuitive since they’re not protected from rain) but the primary benefits of seasoning are the changes to the wood’s chemical composition.

Among other changes, tannins, which are bitter, are reduced and form phenolic acids, which will play an important role during aging. Levels of certain aromatic compounds are also increased, such as eugenol, and syringic and vanillic aldehydes. At this time we also see increases in methyloctalactone (AKA whiskey lactone), a desirable compound described as resembling the aroma of tonka bean (floral, waxy), coconut, or even celery. [2]

Seasoning duration, which in one of the determinants of how a whiskey matures in the barrel, can vary greatly, anywhere from a few months to over three years. In general, longer seasoning is usually considered more desirable.

Kilning is employed after seasoning and involves stacking the seasoned billets in a large oven and slowly heating them. This will bring any remaining moisture in the wood down to the level desired for forming the barrel. But this process also helps to reduce levels of certain undesirable aldehydes responsible for a flaw called ‘plank smell.’ Specifically trans-oct-2-enal, trans-non-2-enal, and decanal, 8, 9 and 10-carbon aldehydes. (Think of the aroma of newly sawn lumber.)

Charring and Toasting

The second round of degradation occurs after seasoned/kilned staves are finished and formed into a barrel and before the heads are added. The interior is exposed to heat sources that, dependent on temperature and duration, result in the charring or toasting of the wood surface. Whiskey barrels are almost always charred, it’s required by law for Bourbon and rye, but they may also first be toasted (i.e. these are not exclusive processes). In both cases the heating results in more a extreme breakdown of wood structure than was experienced during either seasoning or kilning. This makes it easier for compounds in the lignin to wash out into the distillate and for the distillate to be absorbed by the barrel. The application of heat will also result in the formation of new types of compounds.

Charring is achieved by the direct application of intense heat to the interior of the barrel at temperatures hot enough to cause the wood to quickly and evenly catch fire. The heat source is usually a large natural gas flame. The resulting amount of ‘char’ is measured in terms of its level, using a scale of 1-4, with a ‘1’ affecting just the top surface of the wood and a ‘4’ being deeply burnt. Typically whiskey barrels receive a level 3 or 4 char, however the scale is rather arbitrary and subjective. Knowing the exact number of seconds the barrel interior is allowed to burn is a better metric. Regardless of the designation, the interior is usually burnt to depth of a few millimeters and results in a distinctive fissured surface.

A charred barrel provides several benefits to the maturation process. First, the fissures and texturing created at higher char levels increase the surface through which the whiskey may penetrate the underlying barrel wood. In essence the surface area of the barrel is expanded. Second, the char is said to absorb (‘scrub’) sulfur-bearing compounds out of the distillate (though in well made distillate, these should already be minimized). Finally, the char adds color, along with tannins in the wood, and some aromas. American whiskey drinkers frequently confuse aromas from the charred wood with phenols from peat and describe the whiskey as being ‘peaty’ or ‘smokey’.

In contrast, toasting is a gradual and prolonged heating of the interior of the barrel and thus penetrates deeply into the wood without burning it. The heat source is usually a moderated (low/small) gas flame but there are also techniques involving the use of infrared (IR) lasers. Toasting, if desired, is done before charring. The result is the formation of a wide variety of compounds, somewhat dependent on how long and deeply the wood is heated. These include a range of phenolic aldehydes, guaiacol and syringol (which can impart smoky, spicy, even tar-like aromas), and ketones (which can provide aromas of freshly baked bread and caramel). Finally toasting can also result in the breakdown of cellulose to form glucose, which then undergoes a Maillard reaction (caramelization) to create aromatic compounds such as furan aldehydes, which contribute the aroma of almond or marzipan.

Protocols and Treatments

In recent years cooperages have been working, usually in conjunction with the distilleries, to develop their own special ‘protocols’ for degrading the wood used for their barrels, specific combinations of each of the techniques described above. Protocols like these may also involve more careful selection of the staves themselves, e.g. structure of the grain, to isolate qualities considered desirable by a particular distillery. The staves may also be milled to change/sculpt the interior surface of the barrel before charring or toasting. All this work builds on basic wood research that cooperages have been doing for many years. There’s also been a recent increase in the use of post-maturation finishing treatments, most notably those being used by Makers’ Mark for their ’46’ and ‘Private Select’ Bourbons. One advantage of these treatments is that they can involve types of oak (or other woods) that might otherwise not lend themselves to being formed into a ‘tight’ barrel due to their grain structure but which might contribute interesting/unusual organic compounds to a whiskey.

—

Notes:

[1] The last article included a link to a video showing how quarter sawing works. Here’s that link again: Bowmore Wood Part 6/20 – Quarter Saw Stave Yard Kentucky

[2] Here is a link to a list of wood compounds I provided in the previous article.