About a week ago and somewhat spontaneously I found myself drifting off script the we’re supposed to follow when giving tours at Four Roses just a little further than usual [1] when talking about barrels. I’m not sure what triggered this though the information I started sharing has been rattling around in my head for several years. But whatever the cause, it has left me in the mood to write up a whole bunch of things I’ve learned about American white oak for this journal.

Not just a single species

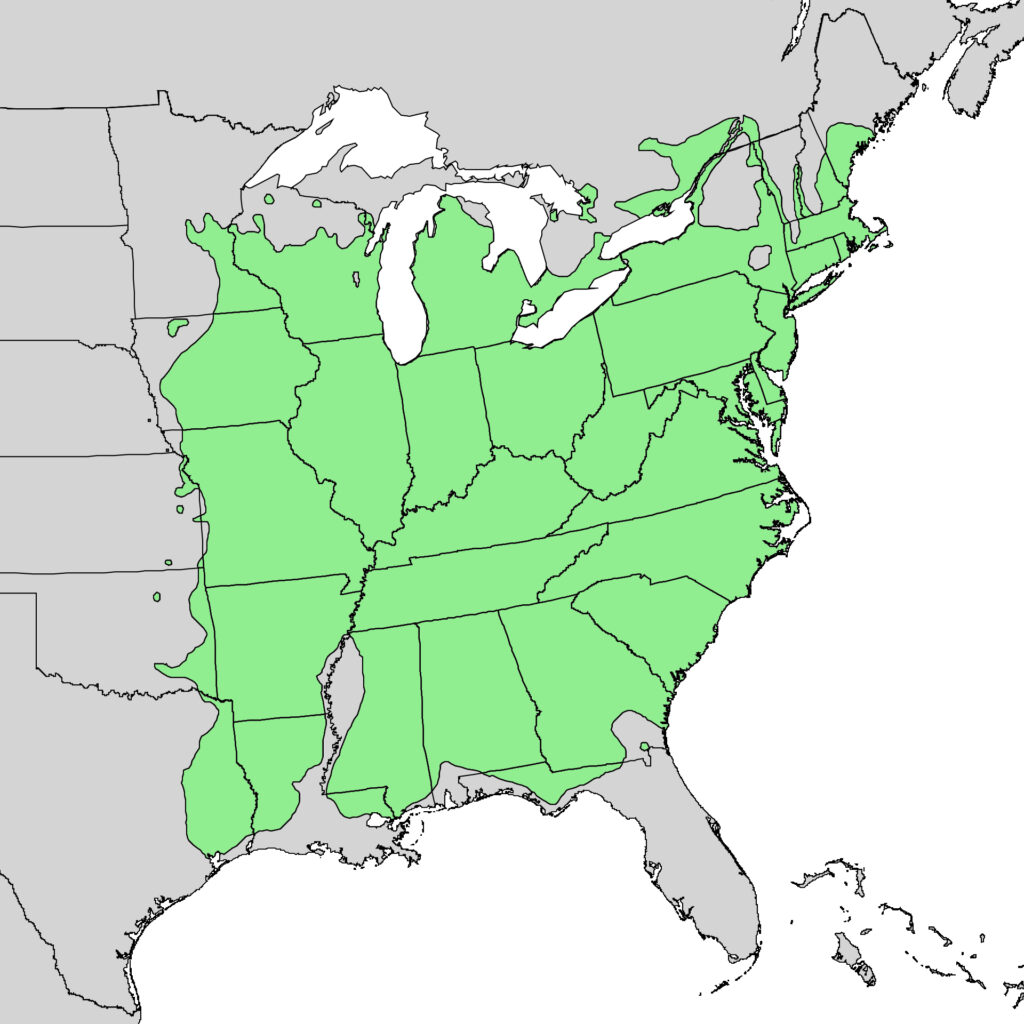

So first off, when we say “American white oak,” we’re really referring to a variety of related species, all of which grow throughout North America. In addition to Quercus alba, the oak used for almost all American whiskey barrels, this group includes:

Q. prinus or chestnut oak

Q. macrocarpa or bur oak

Q. stellate or post oak

Q. bicolor or swamp oak

Q. virginiana or live oak

Q. lyrata or overcup oak

Q. garryana or Oregon white oak

Q. robur or English oak

Of the oaks on this list, the only one I’m aware of being used for aging whiskey (besides Q. alba) is Quercus garryana, sometimes referred to as ‘garry oak.’ This oak is native to the Pacific Northwest (Oregon and Washington) and has been adopted for aging American malt whiskey because of the unique aromas and flavors it contributes. (Think: tomato based bbq sauce. For real!) It’s a protected species, however, so only natural deadfalls can be harvested. It also requires about three years of open air seasoning before it can be used due to the high levels of tannin present in the wood. But the barrels contain a lot of flavor and are usually used multiple times before being retired.

Wide Geographic Distribution, Slow Growth

Quercus alba also has a very wide geographic distribution and grows well across most of the eastern United States, making it an abundant source for barrels. It is nevertheless a very slow growing tree. Trees harvested for whiskey barrels are typically about 80 years old when felled. Surprisingly very little has been done to cultivate reforestation with the trees historically and reliably reseeding themselves. Based on conversation with folks in the barrel industry (cooperages) there’s now concern that changes in climate are affecting the sapling count and natural range. I expect we’re going to see more active forest management in the form of re-planting in the next decade. (See Coda below for more on this.)

Tight Barrels

Another characteristic of American white oak that makes it so suitable for whiskey barrels is that its physical structure makes it particularly easy to construct (or ‘raise’ as coopers like to say) barrels capable holding liquid. Coopers call these ‘tight barrels.’ To understand the nature of this suitability, you first need to know a bit about the structure of wood, i.e. what it’s made of [2]. We’re going to take a bit of a deep dive here!

There are two primary structural components to wood:

Cellulose & Hemicellulose: These are the two polymers that provide the rigid structure of a tree. These compounds don’t generally contribute much to barrel aging unless modified by weathering/heat (degradation).

Lignin: Another class of polymers that fills in the spaces between the cellulose and hemicellulose. When lignin is toasted and charred (more on this below) it will interact with ethanol and oxygen to create many new compounds.

Living trees use a network of vessels constructed out of these structural components that run vertically and horizontally for the purpose of transporting water and nutrients between the roots and the tree top (or crown). This is akin to a circulatory system. When a tree is harvested for timber (and dies) this system is left more or less intact.

Several features of this circulation system make American white oak very structurally well suited for making tight barrels. First, the longitudinal vessels contain structures called tyloses, which seal up when tree is harvested and sectioned. Think of these as little valves. Second, by breaking down the cut sections into staves using a technique called quarter sawing, we maintain the integrity of another somewhat unique anatomical feature of the oak called multiseriate compound medullary rays. Keeping the rays intact as possible ensures that the staves, will not leak across the grain (out of their sides). Together these characteristics make it possible to build a tight barrel.

Here’s a great video with an explanation of quarter sawing:

(Source: Bowmore Wood Part 6/20 – Quarter Saw Stave Yard Kentucky)

A Range of Harmonious Organic Compounds

After all of American white oak’s other great qualities, there is one final bit of serendipity: the amazing array of compounds that contribute directly to the aroma and flavor of a whiskey. Some of these are native to the wood, some are formed during degradation [3][4], and finally some are created during maturation process itself, primarily as ethanol interacts with lignin. When people say as much as 85% of the flavor of a whiskey comes from the barrel, this array of compounds is what they are referring to.

Below is just a partial list of compounds (in no particular order) that can be attributed directly or indirectly to the oak and the environment it provides during maturation, along with the qualities they lend to the whiskey:

Tannins: providing some color and flavor elements

Fatty Acids: form esters with alcohols in distillate

Sugars: e.g. pentose, hexose, glycerol

Lignin: when not degraded, forms compounds with ethanol

Vanillin; Acetovanillone: vanilla

Eugenol/Isoeugenol: clove, spice

Guaiacol: clove

Ethylguiacol: sweet, medicinal

Vinylguiacol: clove, smokey, spicy

Trans-β-methyl-γ-octalactone (whiskey lactone): nutty, smoke, astringent

Cis-β-methyl-γ-octalactone (whiskey lactone): nutty, smoke, coconut, woody

Cinnamaldehyde: cinnamon

Syringaldehyde: aroma is spicy, smokey; taste is sweet fruity cherry spice nut

Coniferaldehyde: roasty/toasty, sweet baked goods

p-coumaric acid: balsamic vinigar notes

Benzoic acid: can form pleasant smelling esters with ethanol

Ketones: bready/caramel

Furans: (Maillard reaction products): almond and marzipan

Coda

As required by 27 CFR 5 where the standards of identity for Bourbon and rye are defined, both whiskey types must be aged in new oak containers (barrels) which have been charred. As I have touched upon elsewhere, the ‘new’ requirement just magically came into existence after Prohibition when the modern standards were first written. That standard has obviously been beneficial to the timber and coopering businesses but it places a lot of stresses on oak supplies. We’ve been okay with this in part because demand for barrels remained low during the years people shunned whiskey for ‘white spirits’ like vodka and white rums (1950s – 2000s). But with Bourbon and rye sales out the roof that’s no longer the case.

A couple of forks in the road now seem inevitable. First, closer forest management is probably already warranted, whether that’s through more careful harvesting and/or replanting. That’s not going to alleviate demand in the short term but we need to do something proactive. Second, the industry as a whole should more closely investigate the differences in the qualities of Bourbons and ryes aged in new versus used reconditioned barrels over a sufficiently long period of time: four to eight years [5]. There’s a lot to be said for using a barrel that’s been depleted of some of it’s initial load of tannins. Just look at what the Scots do with them. And while you can make such a whiskey in the U.S. today, the best you can do naming it is to call it ‘whiskey made from a Bourbon mash’ which is a terrible play from a marketing and sales point of view. You might have made something incredible but it’s going to be a tough sale. It would be nice if we had a better and more attractive standard for labeling whiskies like these to help promote barrel reuse.

—

Notes:

[1] There’s a script to follow for our all our tours and we’re not supposed to deviate from it. I’m definitely drifting more than a bit by including these details.

[2] Yes, ‘wood’ is actually made of something.

[3] The processes of seasoning, charring and toasting are all forms of wood degradation. These are crucial to the formation of many aroma and flavoring compounds in whiskey. I’m going to cover this topic in its own article at another time.

[4] Degradation, particularly kiln drying, also reduces compounds responsible for so-called ‘plank smell’ in whiskey. These are trans-oct-2-enal, trans-non-2-enal, and decanal, 8, 9 and 10-carbon aldehydes.

[5] I like to think the big industry players have looked into this already—there’s not much they don’t investigate. The fact they haven’t brought such a product to market might reflect what they felt was a lackluster result. On the other hand, they also don’t yet have the incentive so long as they have long term contracts for new barrels, i.e. don’t mess with success. But for smaller players, especially the one’s without barrel contracts, used reconditioned cooperage might be a great opportunity.

![Read more about the article A Guide to Guides for the American Whiskey Novice in the 1990s [Part I]](https://americangrain.stream/wp-content/uploads/2023/03/Signet_Detail_IMG_3598-300x161.jpg)

Pingback: The Importance of Degrading Oak to Whiskey Maturation – In the American Grain